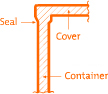

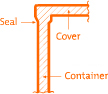

Construction

The positive plate is richly filled with the best suitable, high performance active materials, being produced by Shimazu Ball Mill Lead Oxide Machinery. This Lead Oxide machinery is a specially developed technology, which can produce very small and soft materials. Also, our positive plate consists of glass braided fibre tubes and anti-corrosion alloy cores. The glass fibre contributes to a mechanical strength especially under high temperatures. The plate employs lead alloy cores that offer outstanding corrosion resistibility and mechanical strength. Therefore, our positive plate offers an unsurpassed retaining capacity of active materials.

|

Outstanding impact resistance

The container and the cover are made of synthetic resin, which is ten times as rigid as ebonite. The cover is sealed into one body with the container through heating method.

|

|

Zigzag type separator

The polyethylene zigzag type separator is superior to the leaf type separator by agitating of electrolyte with gas arising during charging. It is well suited for traction batteries that repeat deep charging and discharging with tall containers to avoid stratification of electrolyte.

|

|

Easy maintenance and handling

The orange float on top of the vent cap provides for a simple method to observe low electrolyte levels. The highest electrolyte level can be easily determined and the required amount of water can be put into the cell by opening the vent caps. A ‘one touch operation’ assures the opening and closing of the vent plug. Application of the swan screw assures free choice of the on-off direction. Water filler and water tank are both available.

|

Cell specifications

|

Discharging characteristics of a storage battery for forklift trucks

Each hour rate (an example) just after fully charging, temperature of battery: 30ºC, Discharging rate C: rated one.

|

|

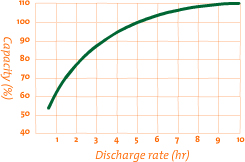

Relation between discharge rate and capacity

The value of current (A) in each discharge rate of a storage battery of which 5 hour rate capacity is 400 Ah is as shown below:

5 hour rate (5 HR)=400Ah/5=80 A,

3 hour rate (3 HR)=400 Ah x 0.85/3=113A,

2 hour rate (2 HR)=400 Ah x 0.75/2=150A,

1 hour rate (1 HR)=400 Ah x 0.6/1=240A.

|

|

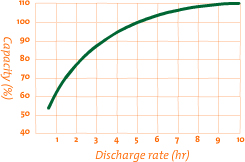

Relation between temperature and capacity of a battery

As seen from the figure shown on the left, a forklift truck battery's actual available working time is shorter in winter than in summer. Especially in case of working in a refrigerated warehouse, the available working time of a battery is conspicuously shortened due to high frequency of lifting works made. As a countermeasure against the problem mentioned above, it is recommended to charge a cold battery to be in a little overcharged condition and besides to warm up the temperature of it in advance. (The most suitable temperature of the battery in this case seems to be about 30º C).

|

|

Life of clud type storage battery for forklift truck

Depending on the use and conditions, etc. of a forklift truck, in ordinary cases the life of a storage battery is indicated by its endurable years for use or capable cycles between charging and discharging before the capacity of the battery has decreased to 60%-80% of the rated one. |

|